생물기기분석 실험 1

1. 제목: 미생물의 액체 배양 및 생장곡선

2. 목적

(1) 미생물의 액체 배양 배지 조제

(2) 미생물의 배양

(3) 미생물의 생장곡선 작성

3. 실험 방법

(1) 미생물의 액체 배지 조제

1) 배지 성분

a. 탄소원: 20.0 g/L glucose

b. 질소원: 2.5 g/L yeast extract

c. 미량원소: 5.0 g/L K2HPO4

1.0 g/L NaCl

0.2 g/L MgSO4․7H2O

0.6 g/L (NH4)2SO4

2) 포도당을 제외한 배지 성분을 포도당 농축액을 첨가할 양을 고려하여 일정한 양의 증류수에 마그네틱 바를 사용하여 녹인다.

3) 포도당을 제외한 액체 배지의 pH를 pH meter를 사용하여 pH 7.0으로 조절한다.

4) 완전히 녹인 후에 고압 멸균기(autoclave)를 사용하여 121℃에서 15min 동안 멸균한다.

5) 포도당은 10 배 농축액 (200.0 g/L)를 별도로 만들어 멸균한 후에 포도당을 제외한 배지 성분을 멸균한 후에 첨가한다.

(2) 미생물의 접종 및 배양

1) 실온으로 식힌 액체 배지에 전배양액을 접종하여 미생물을 배양한다.

2) 사용한 균주가 섬유소 분해효소 생산균주인 B. amyloliquefaciens DL-3인 경우에는 37℃에서 3~5일간 배양하여 균체의 성장 및 섬유소 분해효소의 생산을 측정한다.

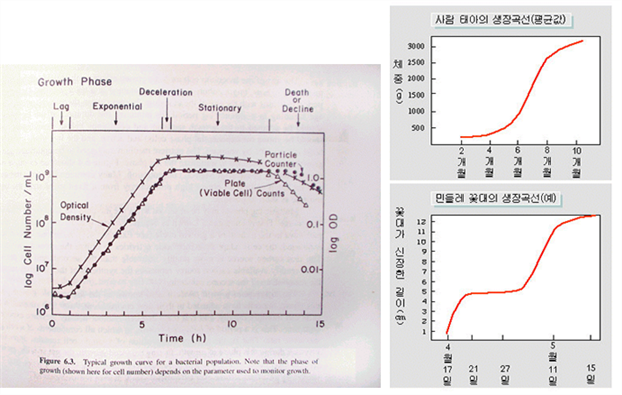

(3) 미생물의 생장곡선 작성

1) 각 시간대 별로 채취한 시료의 pH 및 흡광도 (OD; optical density)를 측정한다

2) 건조중량 (dry cells weight) 측정

a. 일정한 부피의 배양액을 원심분리기를 사용하여 균체를 침전시킨다.

b. 상등액을 제거한 후에 배양액과 같은 양의 증류수를 첨가한 후에 voltex mixer를 현탁시킨다.

c. 현탁한 배양액을 원심분리하여 균체를 침전시킨다.

d. 상측액을 제거한 균체에 배양액과 같은 양의 증류수를 첨가한 후에 현탁시킨다.

e. 현탁액을 미리 건조하여 무게를 측정한 알루미늄 접시에 붓는다.

f. 건조기를 사용하여 95 ~ 120℃에서 일정한 시간 건조한 후에 무게를 측정한다.

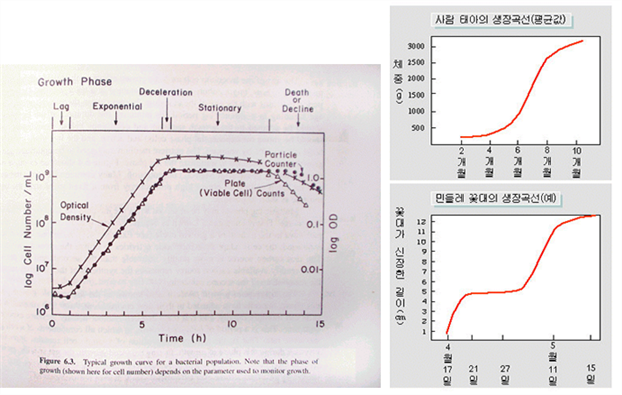

(4) 미생물의 생장곡선 작성 예

4. 실험 기구

(1) 멸균기 (autocleave)

(2) 원심분리기 (centrifuge)

(3) pH meter

(4) 건조기 (dry oven)

(5) 기타: 저울, voltex mixer, 알루미늄 접시

5. 준비물 및 실험내용

(1) 준비물

1) 배지 조제를 위한 시약

2) 시간별로 채취한 미생물 배양액

(2) 실험내용

1) 배지 조제 및 미생물 배양

2) 준비한 배양액의 pH 및 OD 측정

3) 준비한 배양액의 건조중량 측정

4) 측정한 OD 및 건조중량을 이용한 미생물의 생육곡선 작성

5) 각조에서 배양한 미생물 배양액을 사용한 생육곡선 작성 (option)

6. 결과 및 토의

(1) 배지의 조제에서 포도당을 별도로 멸균하는 이유

(2) OD를 측정할 경우에 알맞은 희석이 필요한 이유

7. 관련 논문 (홈페이지의 논문 및 저서 참고)

(1) Jin, I. H., Y. D. Y. Jung, C. W. son, S. K. Kim, W. Gao, C. H. Chung, and J.W. Lee (2011) Enhanced production of heteropolysaccharide-7 by Beijerinckia indica HS-2001in repeated batch culture with optimized substitution of culture medium. Biotechnol. Bioprocess Eng. 16: 245-255. (참고문헌 19)

(2) Jung, D. Y., C. W. Son, S. K. Kim, W. Gao, and J. W. Lee (2013) Enhanced production of heteropolysaccharide-7 by Beijerinckia indica HS-2001 in pilot-scaled bioreactor under optimized conditions involved in dissolved oxygen using sucrose-based medlium. Biotechnol. Bioprocess Eng. 18: 94-103 (참고문헌 35)