그림 1. 생물산업제품의 일반적인 생산 공정

그림 1. 생물산업제품의 일반적인 생산 공정생물기기분석학 수업노트-7: 생물반응기

- 차 례 -

I. 생물반응기

1. 조건

2. 생물반응기의 기본조건

3. 생물산업제품 생산공정

4. 미생물 배양에 의한 생물산업 제품 생산의 예

II. 생물반응기의 종류 및 구조

1. 생물반응기의 종류

2. 교반반응기의 구조

III. 생물반응기의 parameter 측정 및 조절

1. 온도 (temperature)

2. 압력 (pressure)

3. 회전속도 (agitation speed)

4. 거품 (foam)

5. 통기양 (amount of air flow)

6. 배양액의 무게 (weight)

7. 산소농도 (oxygen)

8. pH (수소이온농도)

9. Redox (산화환원전위차)

10. 이산화탄소

11. 이온농도 (ions)

12. Exist gas analysis

IV. 생물반응기의 제어

- 강 의 내 용 -

I. 생물반응기

1. 조건

(1) 생물체를 배양할 수 있는 최적 환경의 제공 및 유지

(2) 최적환경: 온도, pH, 산소,....

(3) 환경의 유지: 멸균 및 오염방지

2. 생물반응기의 기본조건

(1) 무균적으로 충분한 시간 작동 (reliable)

(2) 동력사용이 최소화로 설계 (less power consumption)

(3) 알맞는 양의 공기 공급과 교반 (aeration & agitation)

(4) 온도 조절 기능

(5) pH 조절 기능

(6) 시료 채취가 용이한 제작 (sampling)

(7) 증발열의 최소화 (evaporation)

(8) 최소의 노동력으로 운영되도록 제작 (minimal labor)

(9) 견고하고 비싸지 않는 재질

3. 생물반응기의 이용과 생물산업제품 생산

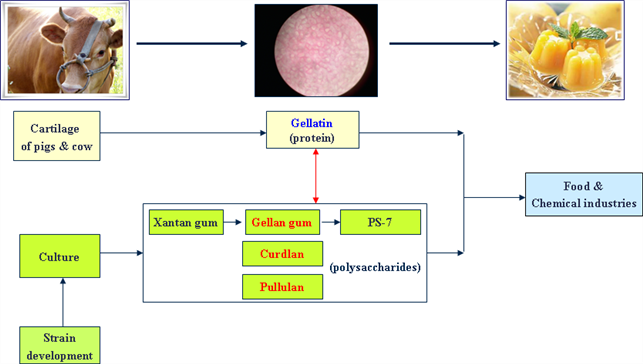

그림 1. 생물산업제품의 일반적인 생산 공정

그림 1. 생물산업제품의 일반적인 생산 공정

4. 미생물 배양에 의한 생물산업 제품 생산의 예

(1) 기능성 다당류의 생산

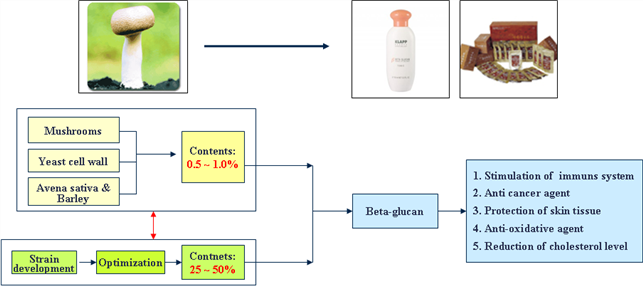

(2) 베타-글루칸의 생산

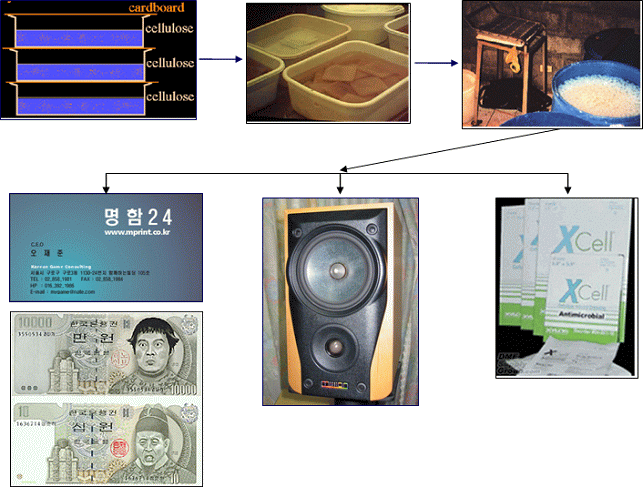

(3) 미생물 섬유소의 생산

II. 생물반응기의 종류 및 구조

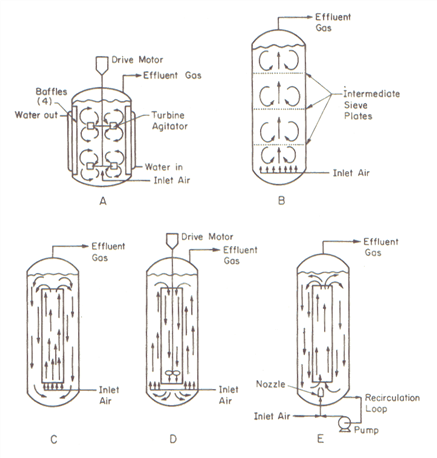

1. 생물반응기의 종류

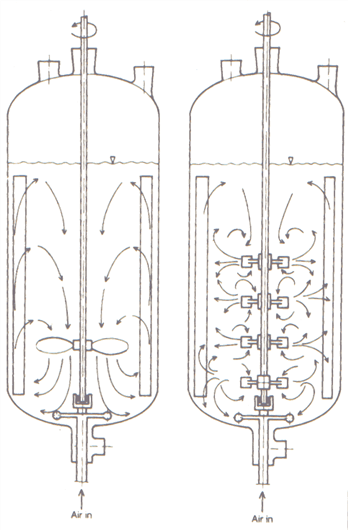

(1) 교반반응기 (stirred-tank reactor): 그림 A

1) 일반적이며 전통적인 반응기

2) 내부에서 기계적으로 교반되는 반응기

3) 높은 기체전달 계수

(2) 기포탑반응기 (bubble column reactor): 그림 B

1) 기체분사 (sparing)에 의하여 교반되는 반응기

2) 낮은 점도의 배지에 적당

3) 에너지 효율이 높음

4) 낮은 전단응력이 요구되는 생물체의 배양

(3) 루프식반응기 (loop reactor): 그림 C, D 및 E

1) 교반반응기와 기포탑반응기의 중간 특성

2) 주입되는 기체의 움직임이나 기계적인 펌프,

3) 또는 두 가지의 조합에 의하여 혼합액과 액체순환이 유도되는 반응기

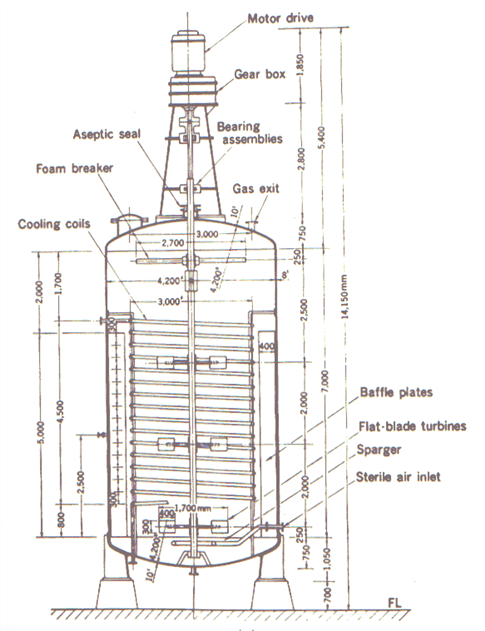

2. 교반반응기의 구조

(1) 일반적 구조

1) vessel

a. 재질: 대부분 stainless steel, 소형의 경우 유리도 사용

- sus316: 액체와 접촉 부분에 사용

- sus310: 뚜껑과 자켓이 사용

b. 높이 대 지름의 비가 2~3: 1

2) 교반축 (shaft)

a. 교반축의 동력 전달 위치에 따라 상부, 하부형

b. 오염 방지를 위한 특별한 seal을 사용

3) 임펠러 (impeller)

a. 임펠러의 지름은 vessel 지름의 30~40%

b. 교반과 기체의 분산 (공급되는 큰 입자의 기포를 작은 입자로 깨트림)

4) 스파자 (sparge): air comperssor에서 만들어진 공기의 공급

5) 배플 (baffle): 방해판

a. 혼합과 기체분산 및 vessel 벽면의 균 증식 억제

b. vessel 지름의 약 8~10%의 너비를 가지는 판

c. 보통 4개를 부착

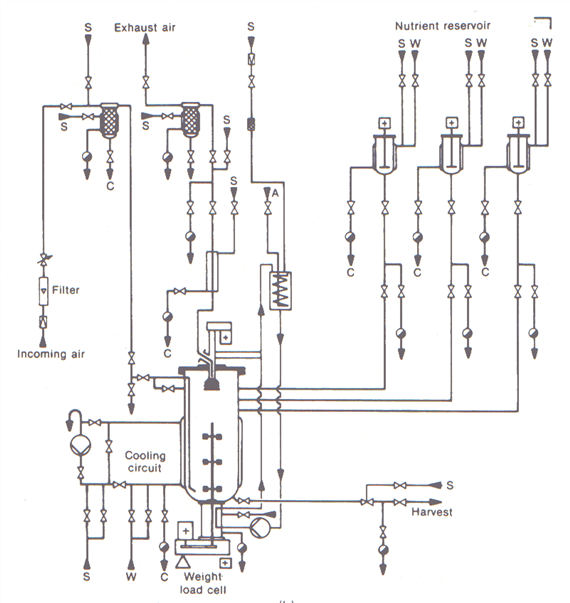

(2) 계측기구

1) 온도 (temperature): 온도계 (thermometer) 또는 온도센서 (thermistor)

2) 압력 (pressure) : tube pressure gauge 또는 diaphram sensour

3) 회전속도 (agitation speed): wattmeter 또는 strain gages

4) 거품 (foam) : rubber-sheathed electrode

5) 통기양 : rotameters 또는 thermal mass flowmeter

6) 배양액의 무게 (weight): load cell

7) pH (수소이온 농도): pH electrode

8) Redox (산화환원전위차) : redox electrode

9) 산소농도 (oxygen): O2 electrode

10) 이산화탄소 : CO2 electrode

11) 이온 (ions) : 각종 ion electrode

NH3, NH4, Br, Cd, Ca, Cl, Cu, CN, F, BF4, I, Pb,

NO3, CiO4, K, Ag, Na,S, SCN

12) Exist-gas analysis: Mass spectrometer

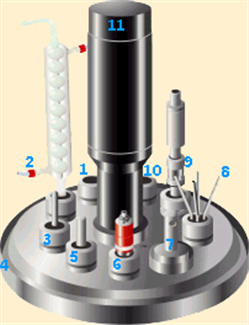

그림 2. 산업용 생물배양기의 일반적인 구조 (50 ton 규모)

그림 3. 생물배양기의 임펠레 개수가 교반에 미치는 영향

그림 4. 생물배양기의 물질이동 흐름도: 스팀, 냉각수, 공기 및 영양물질

III. 생물반응기의 parameter 측정 및 조절

1. 온도 (temperature) (참고: Principle of Fermetation Technol., P148 그림 8-6A)

(1) 일반 온도계

1) 물질의 열팽장계수를 이용한 온도측정

2) 수은 또는 알코올을 사용

(2) 전기전항 온도계

1) 온도 변화에 따른 금속의 저기저항의 차이를 이용하여 온도측정

2) 100Ω의 저항을 가지는 백금을 주로 사용

3) 정확도가 높음

(3) 온도센서 (thermostor)

1) 온도차이에 의한 반도체의 저항변화를 이용하여 온도측정

2) 철, 니켈 등의 금속을 사용하여 만든 반도체를 사용하여 제조

2. 압력 (pressure)

(1) Bourdon tube pressure gauge

1) 용기내의 압력을 측정

2) 압력의 변화가 연결된 측정기의 길이 변화로 나타남

(2) Nested diaphram-type sensor

1) 용기 또는 파이프 내의 압력을 무균적으로 측정

2) 압력의 변화가 pointer에 직접 전달

3. 회전속도 (agitation speed)

(1) wattmeter: 교반모터에 부착된 wattmeter로 동력 소비를 측정

(2) strain gages

1) 축의 회전을 전기적 신호로 변환하여 회전수를 측정

2) 일반 원심분리기의 회전수 측정과 같은 원리

4. 거품 (foam) : antiform sensor (electrode)

(1) probe는 stainless steel로 제작

(2) 거품이 probe의 끝 (tip)에 땋는 순간마다 전기적 신호가 발생

5. 통기양 (amount of air flow)

(1) rotameter

1) 유리 또는 아크릴로 만들어진 관과 이 관에 들어있는 구형의 물체로 구성

2) 수직으로 세워진 관의 구형 물체는 유입되는 기체의 양에 비례하여 떠오름

(2) Thermal mass flowmeter

1) 정확한 양의 산소와 이산화탄소을 측정 (±1% 이하의 오차)

2) 기체가 흐르는 관에 열발생기와 온도측정기를 설치

3) 열발생기를 통과한 후와 전의 기체온도를 측정하여 흐르는 기체양을 계산

4) 계산식

H = Q∙Cp(T2 - T1)

H = heat transferred

Q = mass flow rate of the gas

Cp = specific heat of gas

T1 = temperature of gas before heat is transferred to it

T2 = temperature of gas after heat is transferred to it

Q에 대하여 측정값을 대입하면

Q = H/Cp(T2 - T1)

6. 배양액의 무게 (weight): load cell

(1) 무게에 비례한 장력의 변화로 측정

(2) 금속합금으로 만든 코일형의 측정기

(3) 생물배양기의 밑부분이나 배양기의 측면에 설치

7. 산소농도 (oxygen): O2 electrode

(1) Galvanic type

1) 구성

a. 양극-납, 음극-은

b. 전해질: potassium hydroxide, chloride, bicabonate

c. tefron, polyethylene 또는 polystyrene 막으로 만들어진 sensing tip

2) 원리

a. 막을 통과한 산소의 양에 비례하여 양극간의 전하량이 변화

b. 반응 시간이 느림

(2) Polarographic type

1) 구성: 양극-은, 음극-백금, 금

2) glalvanic type에 비하여 반응속도가 빠름

8. pH (수소이온농도) : pH electrode

(1) combined glass reference electrode로 측정

(2) 전극은 silver/silver chloride

(3) 전해질은 potassim chloride

9. Redox (산화환원전위차): redox electrode

(1) 생물계의 산화환원 전위차를 mV 단위로 측정

(2) Reduced form (negative value) ↔ oxidized form (positive value) + electron

(3) 전극은 백금, 금 등으로 되어있으며 구리합금에 연결되어 있음

10. 이산화탄소: CO2 electrode

∙CO2가 용액에 녹는 양에 비레하여 voltage의 변화

11. 이온농도 (ions): 각종 ion specific electrode

(1) 측정 가능한 이온: NH3, NH4, Br, Cd, Ca, Cl, Cu, CN, F, BF4,

I, Pb, NO3, CiO4, K, Ag, Na,S, SCN

(2) Orion Research & Radiometer에서 개발

12. Exist-gas analysis : Mass spectrometer

IV. 생물반응기의 제어

(1) 목적: 생산물을 생산하기 위한 최적 조건으로 유지하기 위해 매개변수들을 측정하고 조절

(2) 측정해야할 사항

1) 온도

2) pH

3) 발조내의 압력

4) 교반속도 (교반에 필요한 동력량)

5) 통기량

6) 거품형성

7) 기질의 공급속도 (연속 배양시): load cell을 이용

8) 발효조내의 배지 수준 (양) (working volume)의 측정

9) 배지의 점도측정 (viscosity): 생산성을 추정

10) 배지의 혼탁도 측정 (Optical density): 균의 증식

(3) 측정 방법

1) insertable probe

a. pH

b. redox potential: 산화, 환원의 차이를 전위차로 표시

c. ion electrodes: Br, Cd, Ca, Cl, Cu, CN....

d. DO probe

e. CO2 probe

f. fluorscence probe (NADH)

g. biosensors

2) exit gas analyzer: CO2, O2

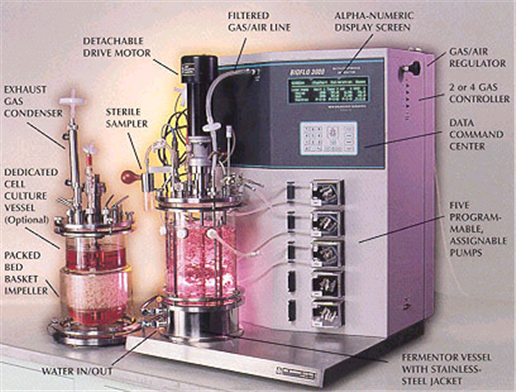

(4) assembly of inserted probes

그림 5. 일반적인 실험실 규모의 생물배양기 (5 ~ 7 L)

1) Headplate

a. Thermowell for platinum RTD Sensor* h. Base addition

b. Ring sparger i. Inoculum (Septum)

c. Harvest tube j. Exhaust gas condenser

d. Sampler assembly k. Foam level detector*

e. D.O. electrode* l. Anti-foam addition

f. pH electrode* m. Spare ports

g. Acid addition

2) Side wall

a. Four process ports

b. Without ports (optional)

3) Heat exchanger

2-Side-entry probe ports (optional)

(5) headplate의 구조

1) Sparger port (공기 공급)

2) Condenser: 액체의 증발을 방지

3) Temperature port (온도 측정): temperature probe in a blind pocket

4) Clamp: vessel easily uncouples to facilitate cleaning and autoclaving with simple one touch clamp

5) Sampling port

6) pH sensor port

7) Inoculum port

8) Peristaltic pump port: 산, 염기 및 영양물질의 무균적 공급

9) DO sensor port

10) Foam sensor port: 거품 발생 확인

11) Motor with speed encoder: 교반

(6) 여러 가지 생물배양기